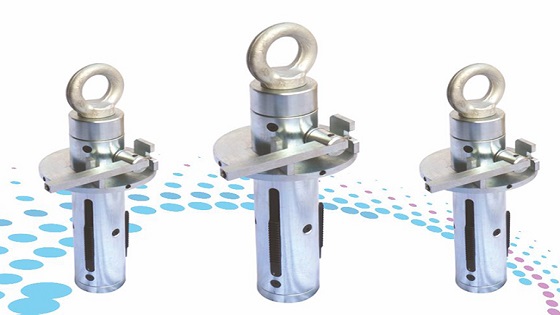

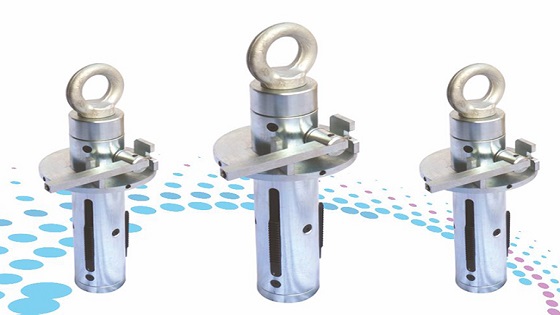

Printing machinery is used in various industries for printing, packaging, and labelling purposes. These machines can be heavy and difficult to move around. Reel lifters are designed to move and lift these heavy printing reels with ease. They are commonly used in the printing industry to transport and handle reels of paper, film, and foil. In this blog post, we will discuss the different types of reel lifters for printing machinery and their uses.

Types of Reel Lifters:

-

Manual Reel Lifter:

Manual reel lifters are the simplest and most affordable type of reel lifters. They are operated manually, and the user has to apply force to lift the reel. These lifters are suitable for smaller and lighter reels, and they can lift reels up to 100 kg. Manual reel lifters are compact and easy to store when not in use.

-

Electric Reel Lifter:

Electric reel lifters are powered by a battery or electricity, and they require minimal effort from the user. They can lift heavier reels than manual reel lifters, up to 500 kg. Electric reel lifters have a built-in safety mechanism that prevents the reel from falling, and they are easy to maneuver around tight spaces.

-

Hydraulic Reel Lifter:

Hydraulic reel lifters are the most powerful and heavy-duty type of reel lifter. They are capable of lifting reels weighing up to 2000 kg. These lifters use hydraulic pressure to lift the reel, and they are controlled by a foot pedal or a hand lever. Hydraulic reel lifters are suitable for large and heavy reels that require frequent handling.

-

Pneumatic Reel Lifter:

Pneumatic reel lifters use compressed air to lift and move reels. They are suitable for clean room environments, as they do not produce any sparks or emissions. Pneumatic reel lifters are compact and lightweight, and they can lift reels weighing up to 250 kg. They are also easy to maneuver in tight spaces.

Uses of Reel Lifters:

-

Loading and Unloading Reels:

Reel lifters are used to load and unload reels from printing machines, trucks, and storage racks. They are designed to handle heavy and bulky reels with ease, reducing the risk of injury to the operator.

-

Moving Reels around the Factory:

Reel lifters are also used to transport reels around the factory floor. They can move reels from one machine to another, and they can also lift reels to higher levels for storage.

-

Storing Reels:

Reel lifters are used to store reels on racks or shelves. They can lift reels to high levels, which maximizes the storage space in the factory. Reel lifters with adjustable forks can also accommodate reels of different sizes.

-

Changing Reels on Printing Machines:

Reel lifters are used to change reels on printing machines quickly and safely. They can lift the old reel off the machine and replace it with a new one without any manual lifting. This reduces the risk of injury to the operator and increases productivity.

Conclusion:

Reel lifters Manufacturer in India are essential equipment for the printing industry. They make it easy to handle heavy and bulky reels, reducing the risk of injury to the operator. There are various types of reel lifters available, ranging from manual to hydraulic, and each type is suitable for different types of reels. When choosing a reel lifter, it’s essential to consider the weight and size of the reel, as well as the environment in which it will be used. By selecting the right reel lifter for the job, printing factories can increase productivity and ensure the safety of their workers.