Fine line printing is a specialized printing technique that involves the printing of very thin and precise lines. This type of printing is widely used in high-tech industries such as electronics, engineering, and medical devices, where precision and accuracy are critical. In this article, we will explore the various printing methods used for fine line printing, the applications of fineline printing, and the benefits it provides to these industries. We will also delve into the specific requirements of fine line printing projects, such as the desired line width and spacing, substrate type, and volume of printing needed. Join us as we explore the fascinating world of fine line printing and its role in advancing technology and innovation.

- Definition: Printing of precise, thin lines for high-tech industries.

- Methods: Screen, flexography, gravure, and digital printing techniques used.

- Applications: Printed circuit boards, RFID tags, sensors, and more.

- Benefits: Provides precision and accuracy in high-tech industries.

- Requirements: Specific line width, spacing, substrate, and volume needed.

- Importance: Fine line printing plays a critical role in advancing technology.

1. Definition: Printing of precise, thin lines for high-tech industries.

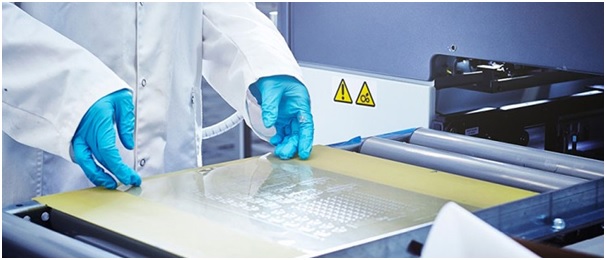

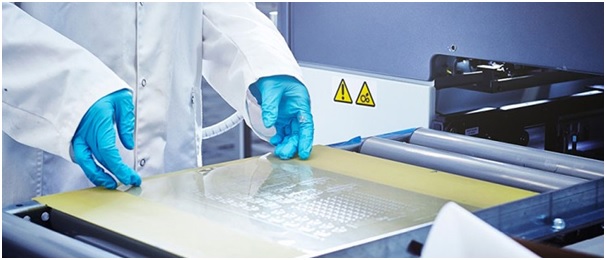

Fine line printing is a specialized printing technique that involves the printing of very thin, precise lines on a substrate. This type of printing is widely used in high-tech industries, such as electronics, engineering, and medical devices, where precision and accuracy are critical. Fine line printing requires specialized equipment and techniques to achieve the desired level of precision, often requiring magnification and specialized inks.

The precise nature of fine line printing makes it ideal for creating intricate and detailed designs, as well as for producing high-tech components with intricate features. Fine line printing is also commonly used in the production of printed circuit boards, which require the printing of conductive lines to connect components.

The development of fine line printing has played a critical role in the advancement of technology and innovation, enabling the creation of complex high-tech products with increased precision and accuracy. Fine line printing is also an important aspect of research and development in many fields, including microfluidics, biosensors, and microelectronics, where the ability to create precise features is critical.

2. Methods: Screen, flexography, gravure, and digital printing techniques used

Fine line printing can be achieved through various printing methods, including screen printing, flexography, gravure printing, and digital printing. Each method offers unique benefits and is used based on the specific requirements of the project. Screen printing uses a mesh stencil to apply ink onto the substrate, while flexography uses a flexible printing plate to transfer ink onto the substrate. Gravure printing uses an engraved cylinder to apply ink onto the substrate, and digital printing uses a computer-controlled system to print directly onto the substrate. These methods provide high precision, accuracy, and repeatability, making them ideal for fine line printing in high-tech industries.

3. Applications: Printed circuit boards, RFID tags, sensors, and more

Fine line printing has various applications in high-tech industries. Printed circuit boards, for instance, require precise printing of conductive ink to connect components. RFID tags and sensors also require fine line printing to achieve the desired functionality. Fine line printing is also used in medical devices, such as biosensors and lab-on-a-chip devices, to create microfluidic channels and other critical features. Additionally, fine line printing is used in the production of photomasks, which are used in the manufacture of microelectronic devices. Overall, fine line printing plays a critical role in advancing technology by providing precision and accuracy in the production of high-tech products.

4. Benefits: Provides precision and accuracy in high-tech industries

Fine line printing offers several benefits to high-tech industries, primarily due to its ability to provide precision and accuracy in the production of intricate and detailed designs. The ability to create precise lines and features is essential in the production of high-tech components such as printed circuit boards, microfluidic devices, biosensors, and other critical components used in medical and engineering applications.

In addition to precision, fine line printing offers several other benefits, such as improved repeatability and consistency in the production process. The use of specialized equipment and techniques ensures that each print is accurate and consistent, reducing the need for manual inspection and adjustments.

Furthermore, fine line printing allows for the production of high-quality components at a faster rate than traditional manufacturing methods. This increased efficiency is critical in meeting the demands of high-tech industries where speed and accuracy are essential.

Overall, the benefits of fine line printing in high-tech industries are significant, offering increased precision, consistency, and efficiency in the production of critical components. Fine line printing is a key enabling technology that has played a crucial role in the advancement of technology and innovation, enabling the creation of increasingly complex and sophisticated products.

5. Requirements: Specific line width, spacing, substrate, and volume needed.

Fine line printing requires specific requirements for the line width, spacing, substrate, and volume to ensure the accuracy and precision of the final product. The line width and spacing are critical factors in fine line printing, as they determine the level of detail and precision that can be achieved. The substrate, or the material that is being printed on, must also be carefully selected to ensure that it is compatible with the printing method and ink used.

Additionally, the volume of printing required must also be considered. High-volume production may require specialized equipment and techniques to ensure consistent and efficient production. In contrast, low-volume production may be able to be achieved using manual or semi-automatic processes.

Overall, the specific requirements for fine line printing must be carefully considered and tailored to the specific needs of each project. This requires an understanding of the materials and processes involved, as well as the ability to select the appropriate equipment and techniques to achieve the desired level of precision and accuracy. Through careful consideration of these factors, fine line printing can be used to create intricate and detailed designs that are critical to the production of high-tech components.

6. Importance: Fine line printing plays a critical role in advancing technology.

Fine line printing is a critical technology that plays an essential role in advancing many high-tech industries, including electronics, engineering, and medical devices. The ability to create precise, intricate features with accuracy and consistency is crucial in the production of high-tech components such as printed circuit boards, sensors, and microfluidic devices.

Fine line printing has enabled the production of increasingly complex and sophisticated products, from small electronic devices to advanced medical equipment. The ability to create precise and detailed designs has allowed for greater efficiency and reliability in many industries, resulting in higher quality products with improved functionality.

The development of fine line printing has also been a key driver of innovation, enabling new products and applications that were previously impossible to achieve. The precision and accuracy of fine line printing have opened up new opportunities in fields such as biosensors, microfluidics, and microelectronics, enabling new research and development in these critical areas.

Overall, the importance of fine line printing in advancing technology cannot be overstated. It has enabled the creation of increasingly complex and sophisticated products, opened up new opportunities for innovation, and played a crucial role in many high-tech industries’ success.

In conclusion,

fine line printing is a critical technology that plays a vital role in advancing high-tech industries. Its ability to create precise, intricate features with accuracy and consistency has enabled the production of increasingly complex and sophisticated products. Fine line printing has opened up new opportunities for innovation and research, and its importance in high-tech industries cannot be overstated. As technology continues to evolve, the role of fine line printing in enabling progress and innovation will only become more critical.